Shedding weight often means shedding features. The ability to adjust your ski bindings to various boot lengths is one such feature that is commonly jettisoned on race bindings. If you know you’re going to be using a particular boot for a season or two, why carry an extra ounce or two?

But weight isn’t the only reason to go fixed. There is beauty and reliability in simplicity; one less thing to jam, strip, or break. Removing adjustment mechanisms also tends to lower pin heights, which is helpful if you’re targeting a neutral stance. For all the above reasons, we tend to recommend fixed mounts if you have reasonable confidence you’ll be in the same boots for at least a season.

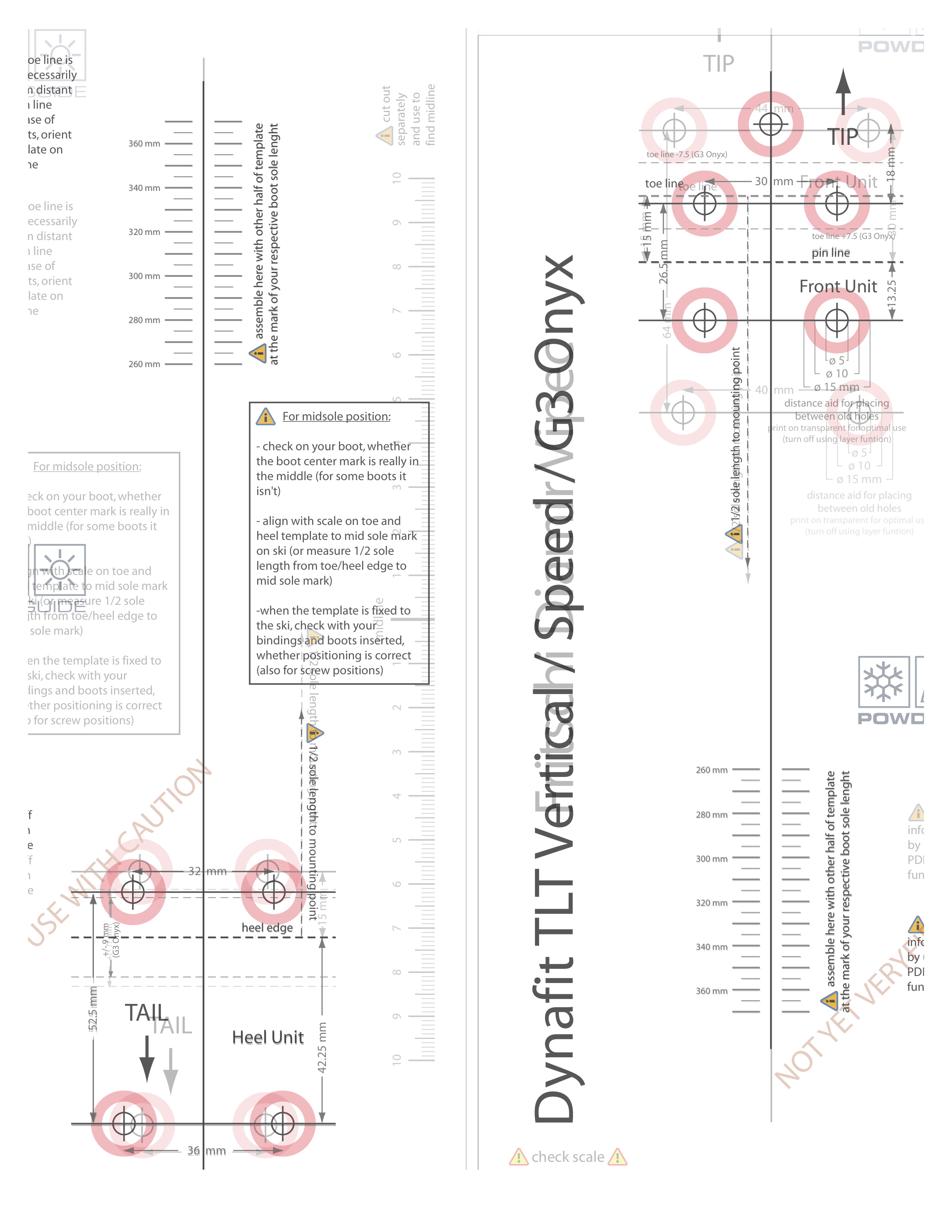

Binding Mounting Next Adventure is a certified service center for all currently manufactured bindings. We can mount most bindings manufactured in the ski industry. We use a mounting template, which is provided by the manufacturer to ensure all holes are drilled correctly. The Royal Family bindings that define the standard of modern freeskiing. You’re looking for power transfer, reliability and the coolest looks – you got it. DIN setting 6.0 - 16.0.

We make that recommendation knowing there is a fallback plan. If you do end up changing boots or selling your skis, you can add adjustment plates at that time. Almost every tech binding can be mounted onto some combination of toe and/or heel plates using special hardware. The plates are then mounted onto your skis, usually with the screws that came with the binding.

There are three main types of binding adjustment plates: bolt-tension, bolt-positioning, and threaded-hole. Each is detailed in its own section below.

Tension Plates

Bolt-tension plates are the most common and consist of simple tracks along which adjustment screws can be slid. Resistance to fore/aft movement is proportional to how tightly the bolts are fastened into nuts mounted underneath the plate. Because of this fact, it’s a natural instinct to want to overtighten the bolts. It’s also tempting to add Loctite or similar thread-locker to prevent the bolts from loosening. However this can lead to stripped screws, for which finding replacements can be difficult. We tend to take the opposite approach and add grease to the threads, making sure to check their tightness on a regular basis. Be careful not to grease the actual plates or nuts underneath, as these surfaces provide the friction that prevents the heels from sliding.

| Tension Plate | Rail Dimensions (WxL) | Mounting Pattern (WxL) |

| Black Diamond Helio | 25 x 71 | 25 x 86 |

| Dynafit Toe | 30 x 37 | 40 x 91 |

| Dynafit 1.0 Heel | 23 x 38/50 | 26 x 54 |

| Dynafit LTR 2.0 | 28 x 31 | 22/40 x 62 |

| Dynafit Superlite 2.0 | 28/34 x 26 | 35.5 x 88 |

| Hagan | 25 x 71 | 25 x 86 |

| Kreuzspitze 14mm | 20.5 x 45 | 32/36 x 52.5 |

| Kreuzspitze 18mm | 20.5 x 49 | 36 x 52.5 |

| Kreuzspitze 40mm | 20.5 x 70 | 36 x 75 |

| Kreuz. Universal | 25 x 62 | 36 x 75 |

| Kreuz. LTR/Superlite 1.0 | ||

| Kreuz. Old LTR | 32 x 60 | 36 x 75 |

| Plum | 20.5 x 70 | 25 x 86 |

| Ski Trab Gara | 25 x 61 | 36 x 75 |

The table above details the dimensions of the adjustment tracks and mounting patterns for various adjustment plates. Combined with binding dimensions, you can determine what plates might work with your binding as well as calculate the approximate amount of fore/aft adjustability. Let’s consider an example.

The Kreuzspitze adjustment plates feature a 20.5mm wide track, which happens to be the mounting width of the Plum race 135/145 heels. Sure enough, that heel/plate combo works great. This means that you can easily swap a Dynafit touring heel with a Plum race heel without re-drilling. That’s because the 14mm “Special K” adjustment plates are drill hole compatible with Dynafit Speed, Radical, Vertical & Comfort heels.

Ski Binding Mounting Jig

To approximate the adjustment range of that combo, start by subtracting the rail length dimension by the mounting length of the heel piece. From this result, subtract another 5-6mm to account for the screw width (or more precisely, two half-widths). The adjustment bolts need to fit in the tracks, after all.

Checking the data tables, the 14mm adjustment plates have a 45mm track and the Plum heel holes are 26mm apart lengthwise. They come with M5 (5mm) bolts. Plugging the numbers into the formula, 45mm – 26mm – 5mm = 14mm. Thus Plum heels have a ~14mm adjustment range when mounted on a Kreuzspitze 14mm plate. We recommend subtracting a couple more millimeters to account for variances in nut shape, hole chamfering, mount location, and discrepancies between stated and measured sole lengths. 12-13mm should be all the adjustment you can expect from this combo.

Now let’s try a more advanced example. The Hagan binding plates feature a 25mm wide track, which happens to be the same length as the Kreuzspitze SCTT heel pieces. Knowing the internal binding mechanics are symmetrical, it’s possible to mount the heels sideways on a Hagan plate. While not necessarily a recommended configuration, we were able to use this combo successfully in a pinch.

One warning when mixing and matching plates and heels across brands. The mounting screws for one brand may not seat properly in the plate holes of another, reducing the amount of threads engaged in the ski. To be safe, we recommend using the binding mounting screws provided by the manufacturer of the plates, noting that these are not typically included.

Positioning Plates

Bolt-positioning plates consist of a linear stage that slides along a leadscrew, actuated with a wrench or driver. Often called rental plates, these devices are faster to adjust and less likely to strip. They are also easier to fine tune for a precise heel gap (heels mounted on tension plates can subtly wander during tightening). The downside is they tend to be heavier and compatible with fewer heel pieces. This is because the stage is drilled and threaded to accept a specific heel pattern. Below are the nitty-gritty details of said patterns.

| Positioning Plate | Heel Pattern (WxL) | Mounting Pattern (WxL) |

| Hagan Rental | 25 x 34 | 25 x 59 |

| Kreuzspitze Rental | 20.5 x 25 | 36 x 75 |

| Ski Trab Flex 30 | 25 x 31 | 45 x 37 |

Threaded-hole Plates

Also known as shift plates, threaded-hole plates consist of multiple sets of holes that exactly match the mounting pattern of the bindings they support. Screw the binding toe or heel into the hole-set that makes the most sense given your boot sole length and desired mounting position. These types of plates are very robust, yet lack the ability to fine tune the binding position since they can only be moved in pre-defined distance increments. Fine-tuning is accomplished with another plate or a binding with a built-in adjustment mechanism. The pre-defined increments are listed below.

Threaded-hole plates are often used in situations where drilling additional holes is suboptimal, usually because the new set would be too close to existing holes or otherwise compromise the integrity of the ski. In this case, you can use the existing holes to mount the plates, and then select another hole-set into which you can screw the binding. Thus you’ve effectively shifted the location of the existing mount.

| Shift Plate | Hole Sets | Increment | Mounting Pattern (WxL) |

| B&D Toe - Classic | 4 | 13mm | 30 x 26.5 (+19) |

| B&D Toe - Radical | 3 | 13mm | 30 x 39 |

| B&D Toe - Outside | 4-5 | 13mm | 47.5 x 79.5 |

| B&D Heel - Inline | 6 | 6mm | 32/36 x 52.5 |

| B&D Heel - Centered | 7 | 6mm | 0 x 27 (+27) |

| Kreuzspitze Toe Shift | 3 | 13.5mm | 36 x 75 |

All of the above plate types can be useful when maintaining a boot quiver as they can help you maintain a centered position on the ski. They are also handy if you aren’t quite sure where you want to be mounted on the ski. One use-case is to mount a ski with some adjustment plates and test skiing it at various fore/aft positions. Once the sweet spot is found, you can then remove the plates and do a fixed mount at the perfect location for your style and boot sole length.

That’s all for now. We hope you’ve found this information helpful. Head on over to our binding section to acquire these tools of the trade.

Through time, equipment as evolve a lot. From no cable pin binding (here), leather boots (here) and tall skinny skis (here) to rigid cable bindings (here), stiff plastic boots (here) and twice as wide skis (here).

A debate of great matter has emerged of this evolution. Where to mount a telemark binding?

To make a long story short, before parabolic skis, telemark bindings simply used to be mounted at the point of balance of the ski. You took the ski, balanced it on one finger and mount the binding pin (the front of the foot) aligned with that point. Ta dam!. In comparison, alpine skis are mounted by placing the binding at the position that will align the center of the boot sole with the center of side cut.

Then, when parabolic side cut was invented in the mid 90’s, the point of balance didn’t match with the center of side cut anymore. At this point, pin bindings where mounted on the center of the side cut.

But over the past decade, the rigidity of boots and bindings has increased dramatically. It affects the way the back ski reacts to the telemark knee drop while turning. On top of that, parabolic skis are not the first criteria skis are bought today. There’s the camber, the rocker, the side cut, the general flex of the skis, it’s width, tapered tail design… So back to square one, where do we mount the telemark modern telemark binding? It is one of the questions I’m most often asked, even by seasoned telemarkers

I found out that no one agrees on any general rule. I’ve asked top telemark skiers from different categories backgrounds and here’s what they had to say:

Big mountain, Paul Kimbrough:

I always struggle with where to mount my skis and often after mounting and skiing them I decide to remount because I don’t like the original mount. I ski on Moment skis and I tend to like a more symmetrical ski, so my mounts tend to be closer to true center than most telemarkers. With 190cm Bibby Pros, I mount about 5cm back from true center, I think boot center is close to side cut center with this mount, maybe a little back… When mounting I do a lot of eyeballing and usually wing it a bit. Hope that helps.

Cheers

PK

Telemark racer, Mathieu Brunet (represented Canada on telemark world cup):

I’ve been mounting my skis half a inch forward of balance center. But now, with technology improvements, I just mount them according to Alpine standards.

Will Johnston, park builder at Schuss Mountain.

Since I ride Here in the midwest, I ride a TON of park and jumps. I ride bomber bishop bindings, so they have three spots you can mount the binding to the plate. they are mounted ski center to boot center, minus the duck bill. but can move them back up to 25mm.

Tucker Vollbrecht, (see my interview with Tucker to learn more about him)

My bindings are mounted with the boot sole center on the manufacturers center line.

Evans Parent, (see my interview with Evans to learn more about him)

With my NTN setup, I always go boot center to manufacturers center line.

More and more, we tend to see exactly that, boot center to manufacturer’s center line. If you don’t know where to start, definitely try that. After all, telemark is getting closer than it ever has to performance of an alpine setup. Here’s an excellent web site that suggest where to mount your skis, depending on brand and models . But beware, people will still debate on the subject for many years to come…

Myth number 1:

If you change your binding’s position, it will affect the structure of your ski and will make it weaker. Nothing is further from the truth. Skis can be remounted many times and it won’t change anything. As PK says, you can change your mind and re-drill your skis to another change binding position. Just make sure you don’t drill too close to the old holes. And fill up the holes with epoxy.

Myth number 2:

Binding position is crucial. Not so true. You can have them mounted where you think it’s the best and you will probably never see the difference. I’ve seen people mount their bindings up to 20 cm back from center and they could still ski. Although this guy ripped the binding off because it was too far out of the ski’s thickest part. If you don’t go to the extreme, you shouldn’t have any problems.

Myth number 3:

Mounting telemark binding is hard. Well, that’s actually true. Black Diamond Equipment as calculated that the forces on screws are and say:

Among many guidelines, these include using a mandatory 8-10 Nm screw torque with 1-hour epoxy. Alpine binding screw mounting torques (2-3 Nm) are not enough for telemark binding forces. Any less torque than 8-10 Nm does not create enough clamping force to over- come upward binding force. As a result, your screws can loosen, resulting in the binding ripping out.

That’s one reason why most telemark bindings companies now build models with 6 screws. To give you an idea, 3 pins Rotofella have 3 screws. Today’s telemark is creating that much more tension.

Aside from tension, the 90 degree angle of the drill bit is the most significant factor of success to a lasting binding installation.

Myth number 4:

You need the jig to mount a binding. Nah. Most companies will provide a paper template. And if not, a good tech will make a template himself and will be able to mount any binding. It just takes more time.

To have a happy binding setup, you should:

- have your binding mounted by a telemark tech that know what he’s doing

- not have them mounted at you regular ski shop

- mount them yourself only if you’re a proven handyman.

I hope that your half as mixed up as you were before you read that post.

Ski Binding Mounting Template

If you are still uncertain, just mount them like Will Johnston recommends (center-to-center minus duckbill)

Don’t forget to subscribe to our free email updates.